Transitioning to the new EU MDR

What are the implications on my Technical File?

The Technical Documentation was previously known as the technical file or dossier under MDD. It contains detailed information regarding how the design, function, composition, use, claims, and clinical evaluation of your medical device meets the General Safety and Performance Requirements (GSPR) under the regulation (EU MDR). Technical Documents are compulsory for all classes of devices (Class I, I Measuring, I Sterile, IIa, IIb, and III). However, no two documents are the same, since it is the type of device that dictates the information contained in the Technical Document.

A Notified Body must review your Technical Document. The exception is those manufacturing Class I devices that are not provided sterile and have no measuring function. Therefore, knowing how to compile and present this information for review by Notified Bodies is crucial.

Ready to take the plunge into European Technical Document requirements?

Timelines for transitioning to the new EU MDR

The transition period of the MDR regulation is currently three years. During this time, manufacturers can put medical devices on the market under current EU Directives, in addition to the new regulation. Therefore, CE certificates issued under the current Directives will remain valid for four years post date of issue.

Following said transition period, devices placed on the market must conform to the MDR. The original deadline dates are below:

- Until 25th May 2020 – certificates under the Medical Device Directive (MDD) are valid.

- From 25th May 2020 to 25th May 2024 – certificates issued under the MDD, before the MDR fully applies, will be valid for up to 4 years.

- Until 25th May 2024 – devices in conformity with the MDR can be certified under the MDR and placed on the market.

- From 26th May 2024 – devices placed on the market must be certified under the MDR.

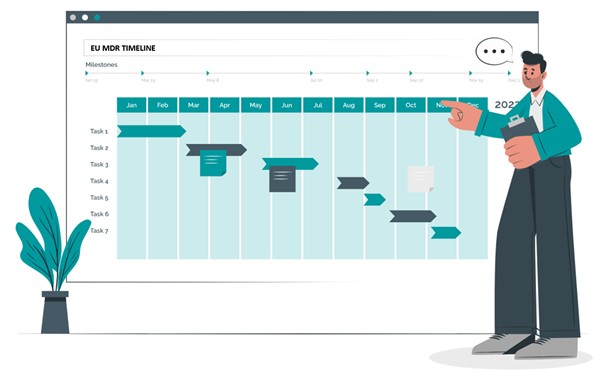

What is the structure of the Technical Documentation?

In accordance with Annex 2, technical documentation is divided into the following sections:

- Device description and specifications, including variants and accessories.

- Information to be supplied by the manufacturer.

- Design and manufacturing information.

- General safety and performance requirements.

- Benefit-risk analysis and risk management.

- Product verification and validation.

So, what are the differences between the CER and PSUR?

While the two reports share some common elements, their purposes are distinct.

The Clinical Evaluation Report shows that the clinical use of a medical device is effective and safe. It interprets all the clinical data found on the device both before and after the product launch.

The Periodic Safety Update Report is only concerned with demonstrating the safety and performance of the post-market data. The PSUR also helps manufacturers demonstrate that their post market surveillance program uses the data available on the market to the notified body. The manufacturer needs to show that they ensure the continued safety, efficacy, and performance of their device. It proves the effectiveness of a proactive post-market surveillance system.

Manufacturers can find descriptions of those requirements below.

What are the MDR technical documentation requirements?

Device Description and Specification, including variants and accessories

We reserve the first chapter for the device introduction. This chapter’s purpose is to inform the reader of what your product is like. This includes, but is not limited to:

- What is it made of?

- Its dimensions.

- How many versions exist?

- If any accessories are required.

- The intended use.

- Who the users of the product are.

It is also necessary to describe how the product works. If warnings or precautions during use are present, and any contraindications.

It is also necessary to explain the system of assigning the basic UDI-DI and UDI-DI, along with a description of the product classification. This needs to include which rules from Annex 8 apply and how classification of the product is done (Article 51).

Information to be supplied by the Manufacturer

The device labels and instructions for use (IFU) must show the information provided in the previous chapter. Point 23 of the GSPRs provides information on the labels and IFUs. This includes the extent of information required on the labels and IFUs, along with how to present this. (See next chapter).

The manufacturer must carefully choose terminology for the language used on labels and IFUs. Labels and IFUs are publicly available documents. The manufacturer must provide them in one of the official languages of the EU and in the language required by the Member State, and control the translation process when producing labels and IFUs in multiple languages.

Be aware that significantly more information, including symbols, may be required on the label. This is applicable even if your product is certified according to the Medical Device Directive (MDD). The label design, and possibly even the packaging of the product, may need to be revised.

To learn more, read: How to comply with the MDR requirements for medical device labels.

Design Information

This chapter will be easy for those manufacturers who start from the beginning and monitor the development of their product. These manufacturers can simply attach the documents that followed the product development. These include procedures, research plans, protocols, results of verification, and validation. However, those manufacturers with products already certified according to the MDD will need to retroactively compile the design documentation. Point 7.3 Design and Development of ISO 13485: 2016 best serves as a guide for the source of information and what elements the design should cover.

Contact CLIN-r+ for more information regarding design and development validation and verification, according to ISO 13485. We can help manage the design and development of medical devices according to ISO 13485:2016, or the Design and Development File template.

Manufacturing Information

A detailed description of your production process is required in this chapter. We advise the manufacturer to use accurate flow diagrams here, where possible. This is also the chapter to list and describe any other companies involved in the production of your product in any way. This includes, but is not limited to: sterilisation, production of particular parts or accessories, and packaging. You should present these companies with their full name and address, with the description of the process performed for you.

We recommend you attach a quality agreement to this section. You should also describe how you control your suppliers as the manufacturer.

General Safety and Performance Requirements

Annex 1 of the MDR, which covers the GSPRs, aims to prove that your product has been designed and manufactured in accordance with all applicable requirements. Thus ensuring its safe use and effectiveness.

We can achieve compliance with the GSPR by using a checklist or table, with columns for applicability, justification, and a method or standard that refers to a particular requirement. You can make a simple “YES” statement when any particular requirement applies. You can also state the method and harmonised or state-of-the-art standard used to prove compliance.

Likewise, a statement must be “N/A” or “NO” when a requirement is not applicable. Justification for why the requirement is not applicable also needs to be provided so that a third party can understand your reasoning. An example of this could be medical devices that are not sterile. For GSPR requirements 11.4 through 11.8, justification could be that the device is not sterile and does not need to be, so this requirement is not applicable.

Benefit-Risk Analysis and Risk Management

Risk analysis and management are a requirement in all elements of the technical documentation when transitioning to the new EU MDR. The preparation of each document listed so far is done from a risk point of view. This is to prove that you have taken all necessary steps and measures to minimise the risks. ISO 14971:2019 Medical devices – Application of risk management to medical devices provides essential guidance for risk management. GSPR chapter 1 lays out requirements that you should use alongside this. To learn more, read How to use ISO 14971 to manage risks for medical devices.

Having a risk management procedure is an essential first step, followed by a risk assessment for your product. It should conduct the assessment for the entire life cycle of the product. This is from design, entry of raw materials into the warehouse, through the production itself, up to the use of the product by the patient or user and disposal. The following step is the introduction of various measures aimed at minimising risks and keeping them at that minimised level. The Failure Mode & Effects Analysis (FMEA) format is the best known of the many formats the risk assessment can take.

After you have performed the risk analysis, a special review of the remaining risks (if any) is necessary. This will determine if the remaining risks are acceptable or not.

Manufacturers must analyse unacceptable risks, even after you have implemented control measures, from the standpoint of benefits in relation to that risk. For examples of benefit/risk analyses, one need look no further than an x-ray device, which is extremely useful for imaging the body. However, you cannot subject pregnant women to an x-ray, as it could cause harm to an unborn child.

Product Verification and Validation

This section covers all the tests carried out to prove your products’ safety and performance, including:

- Biocompatibility.

- Safety regarding chemical components.

- Electricity safety.

- Stability when stored under prescribed conditions.

- Sterility.

- Usability.

- Any other test that proves the performance of the product.

- Clinical investigation.

The protocols or plans and results of these tests need to be attached as documentation for these pre-clinical data. It is important to accompany the pre-clinical data with clinical data acquired by clinical evaluation or clinical investigation. A clinical evaluation evaluates and analyses clinical data connected to a medical device to provide evidence of the clinical safety and performance of the product. Want to learn more about the clinical evaluation and other MDR requirements? Contact CLIN-r+ to discover our 8-step transition process from MDD to MDR.

It cannot be over-stressed that technical documentation is a living document. Therefore, it is essential to register all changes that occur during the entire life cycle of the medical device. You should also not overlook that any competent authorities may demand evidence from your technical documentation at any time. It is your responsibility to provide it.

Technical documentation for post-market surveillance

In accordance with Annex 2, the technical documentation shall state the product’s safety and efficacy before the manufacturer places it on the market. Nevertheless, monitoring performance plays a crucial role in the post-market phase for the identification of risks during practical product use.

The post-market surveillance system requires manufacturers to continuously and systematically monitor products. They should ensure no malfunctions or undetected safety issues exist. Appendix III of the MDR covers the post-market surveillance (PMS) system. This includes the following documents:

- PMS Procedure.

- PMS Plan.

- PMS Reports (for all class I medical devices).

- Periodic Safety Update Report (for classes IIa, IIb and III).

Prepare your technical documentation for EU MDR

The MDR describes the type of documentation required to prove compliance when transitioning to the new EU MDR. However, it doesn’t give explicit information regarding the structure and appearance of the documents. Therefore, the content of all technical documentation will be the same, in contrast to the document and chapter structures. This will invariably differ from manufacturer to manufacturer.

This review shows the quality system documentation’s connection to the technical documentation. You don’t need to put all the quality system documentation back into the technical documentation. Simply stating the link or location where the requested document is located is more than sufficient.

Precise and thorough descriptions are essential when preparing the technical documentation. The more accurately you present and describe your product, the fewer questions you will face during an audit.

CLIN-r+ Recommendation:

Manufacturers should consider these reports as a work stream of data, and one that requires reporting across many areas in various ways. Facilitating this can bring changes to not only an organisation’s IT infrastructure, but also work roles and interdepartmental collaboration.

The MDR transition is certainly challenging, and a good Technical Document framework is key to success. Clin-r+ highly recommends acquiring validated templates. We have formatted templates as required for submission and review of your files. This also makes compiling the documents significantly easier.

CLIN-r+ offers both brand personalised templates and Technical Document and Design Dossier compilation services. We specialise in helping medical device and IVD companies achieve the CE mark. Below are some services we provide:

- Determining conformity strategy, and exactly which materials need to be compiled.

- Performing gap analyses of where you stand.

- Formulating project plans for transition to EU MDR/IVDR, so manufacturers can internally identify resources and formulate a team with the expertise to execute MDR transition.

- Bringing project plans to life internally with a project team dashboard – allowing you to assign your Subject Matter Experts to workflows and start the process.

- Ensuring CLIN-r+ experts are available to execute or support your team to deliver the transition.

- Bringing resources to your projects that you may not have in-house. Including biostatisticians, medical writers, assurance consultants, SLR software, AI data trackers, and more.

To learn more about CLIN-r+ CE Technical File preparation services for medical devices and IVD manufacturers, get in touch!